Igwe ịgbado ọkụ laser ejiri aka

Nkọwa

Igwe ịgbado ọkụ laser nke Obere ụdị ejiri aka na-ejikọta àgwà ndị bụ isi nke ngwaọrụ nwere obere obere na arụmọrụ na-adịghị mma.

FTW-SL-1000/1500/2000 Mini handheld laser ịgbado ọkụ igwe nakweere ọhụrụ ọgbọ nke fiber laser na-onwem na OSPRI handheld laser ịgbado ọkụ isi, nke na-ejuputa oghere nke handheld ịgbado ọkụ na Laser akụrụngwa ụlọ ọrụ. Na uru nke ngwa ngwa ịgbado ọkụ ọsọ na enweghị consumables, ọ nwere ike zuru okè dochie omenala argon Arc (TIG) ịgbado ọkụ, electric ịgbado ọkụ na ndị ọzọ Filiks mgbe ịgbado ọkụ mkpa igwe anaghị agba nchara efere, ígwè efere, galvanized efere na ndị ọzọ metal ihe. Laser ejiri aka.

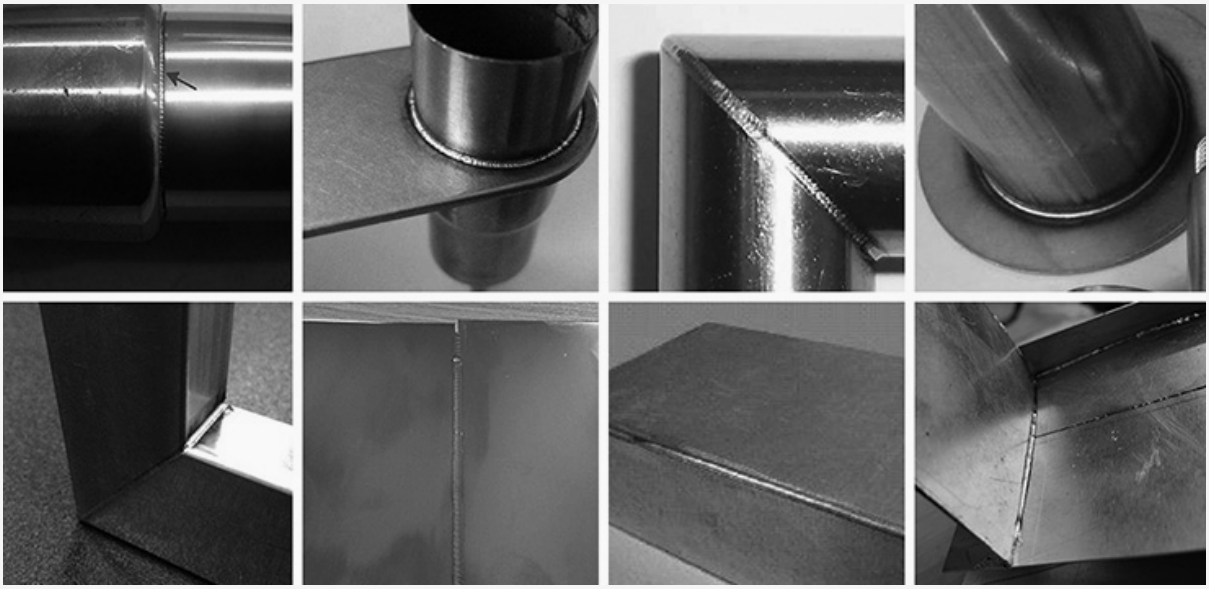

ịgbado ọkụ igwe nwere ike n'ọtụtụ ebe na mgbagwoju na oge ịgbado ọkụ Filiks na kabinet kichin na ime ụlọ ịwụ, steepụ elevator, shelf, oven, igwe anaghị agba nchara ọnụ ụzọ na window guardrail, igbe nkesa, igwe anaghị agba nchara ụlọ na ndị ọzọ na ọrụ.

Nka nka

| Nlereanya | FTW-SL-1000 | FTW-SL-1500 | FTW-SL-2000 |

| Ike Laser | 1000W | 1500W | 2000W |

| Isi iyi Laser | Raycus/Max/IPG/ SUNLITE | Raycus/Max/IPG/ SUNLITE | Raycus/Max/IPG/ SUNLITE |

| Isi Laser | OSPRI | OSPRI | OSPRI |

| Ogologo eriri eriri | 5/10 Mita | 5/10 Mita | 5/10 Mita |

| Ogologo Ogologo Laser | 1070nm | 1070nm | 1070nm |

| Ụdị ọrụ | Nga n'ihu/Mgbanwe | Nga n'ihu/Mgbanwe | Nga n'ihu/Mgbanwe |

| Mmiri mmiri oyi | Hanli/S&A | Hanli/S&A | Hanli/S&A |

| Mpaghara na-emezi ntụpọ | 0.1-3 mm | 0.1-3 mm | 0.1-3 mm |

| Na-emezi nkenke | ± 0.01mm | ± 0.01mm | ± 0.01mm |

| Nha kabinet | 744*941*1030mm | 744*941*1030mm | 750*1260*1110mm |

| Ibu igwe | Ihe dịka 200KG | Ihe dịka 200KG | Ihe dịka 220KG |

| Voltaji | 110V/220V/380V | 110V/220V/380V | 110V/220V/380V |

Atụmatụ igwe

1. Banyere Ogologo eriri eriri eriri

Ọtụtụ mgbe ọkọlọtọ ogologo bụ 10m, ma ọ bụrụ na ị nwere ndị ọzọ mkpa, anyị na-akwado shortening ma ọ bụ ogologo.

2. gas inyeaka: nitrogen ma ọ bụ argon

Ọ bụrụ na mmetụta elu ịgbado ọkụ chọrọ ka ọ dị ọcha ma na-egbuke egbuke, nitrogen ma ọ bụ argon chọrọ.

Ọ bụrụ na ọnweghị ihe achọrọ maka elu ịgbado ọkụ, gbakwunye igwe na-ekpo ọkụ ekpokọtara ikuku, ikuku dị mma.

3. Banyere eriri waya

Ọ bụ nhazi ọkọlọtọ igwe, anyị ga-ezitere gị ọnụ na igwe dum.

4. Akwụkwọ ikike igwe

na-emekarị 2 afọ, anyị nwere ọkachamara mgbe ire otu, 24 hour online.

Ngwa igwe

Fiber Laser welding machine dabara adaba maka ịgbado ọla edo, ọlaọcha, titanium, nickel, tin, ọla kọpa, aluminom na ọla ndị ọzọ na ihe alloy ha. Ọ nwere ike nweta otu ịgbado ọkụ ahụ ziri ezi n'etiti ọla na ọla ndị yiri ya. A na-ejikarị ya eme ihe na mbara igwe, ịrụ ụgbọ mmiri, na ngwá ọrụ. Ngwa igwe na igwe eletrik, ụgbọ ala na ụlọ ọrụ ndị ọzọ.

Nkọwa igwe

RAYCUS MAX SUNLITE Fiber Laser Source Nhọrọ

E jiri ya tụnyere ngwaahịa ndị yiri ya, RAYCUS MAX SUNLITE Fiber laser Source nwere ikike ntụgharị fotoelectric perfor-mance dị elu, ihe kwụsiri ike, yana ikike ntụgharị uche siri ike.

Ike laser nhọrọ dị site na 1000 watts ruo 2000 watts. Anyị nwere R & D na-arụ ọrụ nke ọma na ọkachamara na otu mmepụta ihe, nke bụ àgwà kachasị elu na China. The lasers nwere elu electro-optical ntughari.

OSPRI (QILIN) Isi Welding Fiber Laser

1. Isi ịgbado ọkụ ọkụ

Usoro nke isi ndọta ọdịnala enweghị ike mezue, isi ịgbado ọkụ na-agbado naanị kwesịrị iji 70% nke ike, nke nwere ike ịchekwa ego nke laser; Tụkwasị na nke ahụ, a na-anabata usoro ịgbado ọkụ nke swing, obosara nke nkwonkwo ịgbado ọkụ na-agbanwe agbanwe, na nkwụsị nke ịgbado ọkụ dị ike, nke na-eme ka ọ bụrụ obere adịghị ike nke nkwonkwo laser laser. The ndidi nso na ịgbado ọkụ obosara nke esichara akụkụ na-abawanye, na ezi ịgbado ọkụ akpụ mmetụta na-enwetara.

2. 360 ogo micro ịgbado ọkụ

Mgbe laser doo lekwasịrị anya, ebe nwere ike n'ụzọ ziri ezi positioned na-eji otu ịgbado ọkụ nke obere na obere workpieces iji nweta uka mmepụta.

3. Isi ịgbado ọkụ laser ejiri aka Nozzles

Mgbe anyị nwere eriri eriri laser welder ma dochie nozulu ịgbado ọkụ na mgbụsị akwụkwọ, anyị nwere ike ịkpọ ya eriri laser eji agbado ọkụ na igwe ịkpụ. Ọ bụghị nnukwu aha!

Ọ nwere ike were eriri anya site na eriri eriri eriri wee kpokọta ya na obere ebe iji mepụta laser dị elu maka igbutu ebumnuche. Agbanyeghị, biko mara na ọ nweghị ike igbutu ihe dị oke oke.

Ogo kachasị nke isi mgbado ọkụ Ospri Wobble

1. The wobble ịgbado ọkụ nkwonkwo onwe mepụtara adopts siwing ịgbado ọkụ mode.

2. Enwere ike ịhazi obosara ntụpọ ìhè.

3. The ịgbado ọkụ kpatara ndidi dị ike, nke na-eme ka maka mwepu nke obere laser ịgbado ọkụ ntụpọ, gbasaa ndidi nso na weld obosara nke esichara akụkụ, na-enweta mma weld akpụ.

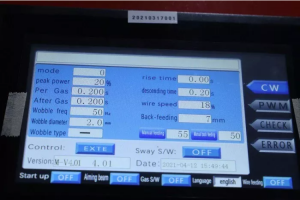

Sistemụ Njikwa OSPRI

Usoro njikwa OSPRI bụ ihe pụrụ iche emere iji mejupụta isi mgbado ọkụ laser OSPRI. Ọ na-abịa na ụdị mode ole na ole, ụdị CW, ụdị PWM Arc ụdị.

Ihuenyo njikwa ozugbo na dijitalụ na-edobe paramita nke eriri waya.

Usoro ahụ na-enyocha ọnọdụ ọrụ ozugbo, nyochaa ma na-anakọta ọnọdụ ọrụ nke laser, chiller, na bọọdụ njikwa.

Na-akwado Chinese, Bekee, Korean, Japanese, Russian, French, Spanish, Israel asụsụ usoro.

Igwe mmiri HANLI maka welder laser (Nhọrọ)

Hanli mmiri Chiller pụrụ iche mepụtara maka eriri laser akụrụngwa, magburu onwe jụrụ mmetụta. arụmọrụ kwụsiri ike na ntụkwasị obi, ọnụego ọdịda dị ala, ike dị mma.

Ihe ntanetịime waya akpaaka

Usoro nri waya nke nwere igwe abụọ na-eme ka nri waya dị nro ma sie ike na-enweghị njigide waya; Nhazi chassis mechiri emechi, nke nwere aka na-ebuli elu na wiil ụwa niile; Onye na-ahụ maka inye nri waya, ihuenyo LED na-egwu ọsọ ọsọ nri waya; Igwe njikwa ọsọ dị elu dị elu, yana ezigbo njikwa ọsọ inye waya.

1000W na 1500W nkwado 0.8mm 1.0mm 1.2mm waya, 2000W nkwado 0.8mm ka 1.6mm.

Waya izipu na azụ ọsọ gbanwee site na aka panel.

Ọ bụrụ na oghere ọla abụọ weld karịa 0.2mm nke chọrọ waya filler.

Uru ngwaahịa

FIBER LASER welding Vs. Mgbado ọkụ TIG dị egwu

AKWỤKWỌ NKE FIBER LASER

Ịrụ ọrụ dị mfe, na-ebelata ụgwọ ọrụ ọrụ. radieshon na-apụtaghị ìhè dị obere. Ngwa ngwa ngwa na arụmọrụ bụ 3-8 ugboro nke argon arc welding.Concentrated ume na obere mmetụta nke thermal deformation.Fine ịgbado ọkụ onuete, miri emi gbazere ọdọ mmiri, elu ike. Enwere ike ịgbado ihe dị oke mkpa, dị ka igwe anaghị agba nchara 0.05mm. Ma autogenous ịgbado ọkụ na mgbakwunye ịgbado ọkụ dị mma.

Mgbado ọkụ TIG dị egwu

Ọkachamara na teknụzụ chọrọ dị elu, nke na-eduga n'ụgwọ ọrụ dị elu. Nnukwu mmerụ ahụ mmadụ. Ọ dị nwayọọ na adịghị arụ ọrụ. The thermal mmetụta dị ukwuu, nke na-eduga ná nnukwu deformation. The onuete ịgbado ọkụ bụ ike siri ike na oge. Ọ chọrọ egweri na polishing. Enweghị ike ịgbado ihe ndị dị gịrịgịrị. Waya ịgbado ọkụ dị mkpa. Ọ dị mfe ịgbado ọkụ.

Nkeji ihe eji agbado ọkụn'ihi na gị akwụkwọ, dị iche iche ihe, dị iche iche ịgbado ọkụ parameters, nanị site na ngalaba, na-egosipụta ozugbo a akụkụ.

Ọ bụrụ na ịchọrọ ịmatakwu gbasara oke, biko kpọtụrụ anyị ozugbo, awa 24 n'ịntanetị.